News

Caster FAQ's

Caster FAQ's

What's the benefit of a 'diamond caster pattern'?

A diamond caster pattern is best for moving heavy loads over uneven surfaces where the rocking effect of the diamond pattern (2 larger casters in the middle and 2 smaller casters on each end) allow you to roll the cart or truck with less strain to move a heavy load over a threshold or uneven surface(s).

What's the benefit of 'two rigid/two swivel casters'?

With larger loads it is much easier to steer with two rigid or fixed casters on one end and two swivel on the other. This allows for the attendant to maneuver the cart or truck with more control and helps facilities prevent from carts hitting walls and doors.

What's the benefit of an 'all swivel caster pattern'?

Four corner all swivel casters are great for smaller loads and where you need to navigate in and out of elevators or in tight spaces, allowing you to roll easily in any direction. For example, if you want to roll a cart directly in front of a washer or dryer in a tight space, having four corner casters simplifies this process. At times, heavy loads will make it harder to steer straight with four corner swivel casters, which can cause a truck to wander or veer. Caution should always be exercised while transporting materials.

Why larger casters?

Why do you need larger casters? Normally they are rated for higher weight capacities. A larger caster will have a larger wheel width, allowing the weight to be more evenly distributed over the width of the wheel, which makes it easier to roll. Semi-pneumatic casters and pneumatic casters will also be quieter when rolling on certain surfaces.

What is a "quiet caster"?

A "quiet caster" normally refers to a semi-pneumatic or full pneumatic caster. These are used in instances where there is a need for less noise ("wheel chatter"). These are usually larger wheel size casters of 6", 8", 10" or greater and have wider wheel footprints with softer material that should always be non-marking. The semi-pneumatic has an air or foam internal channel allowing for cushioning. The full pneumatic is an air filled tire just like a car tire.

Why choose one over the other? Both are expensive but the full pneumatic is usually more costly. Secondly, a full pneumatic can get a flat tire while a semi-pneumatic cannot. Both are quiet and can solve many noise related issues.

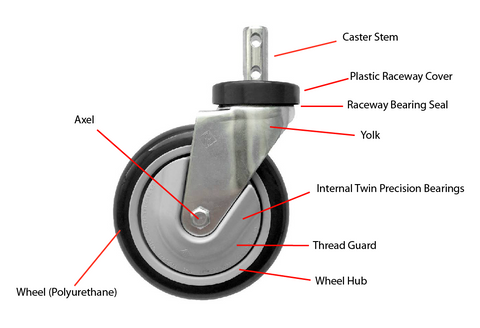

What are the components of a caster?

There are several components to casters – themetal yoke, the top raceway, the wheel and the internalwheel bearings. What are all these? The metal yoke is the housing that the wheel is mounted to, which allows the caster to roll. It is very important to have yokes that areheat treated orcase hardened to make the metal harder and stronger. A yoke that is not heat treated will easily score with a screw driver or hard object, which means the metal is soft and can wear out more easily than if case hardened or heat treated.

Swivel casters have a top raceway where the bearing system allows the caster to rotate 360 degrees - increasing maneuverability. If the yoke is not heat treated these bearings can wear down the inside of the raceway and allow the bearings to become sloppy, causing the raceway to fail.

The material the wheels are made of varies widely and is very important - and softness or hardness matters! Many quality, non-marking wheels are made from polyurethane or TPR (Thermoplastic Rubber). Many other wheels that are less expensive are made of inferior materials which can mark floors. Make sure to ask what the wheels are made of and if they are non-marking. We are proud to say that all R&B casters are non-marking!

The internal bearing(s) for the wheel itself makes it roll smoothly and straight. Inexpensive casters may not even have a wheel bearing. Open bearing systems are vulnerable to debris, which make them noisier and less efficient. A single or dual sealed bearing system is much more desirable as it enhances their effectiveness and life. A sealed bearing prevents debris from damaging the bearing which keeps the caster rolling smoothly for years. In the end you get what you pay for, so know what you are buying.

Caster Maintenance

Keeping your laundromat clean and tidy shows customers that you are concerned about their positive laundry experience. Your customers use your laundry carts as much as, or more than, your washers and dryers. Customers also expect all of your equipment to be in top-notch shape. This helps bring customers back and creates ongoing revenue!

Just like all other laundromat equipment, laundry carts need to be maintained too. Taking care of your laundry carts shows your customers that you care. Taking the time to clean your carts and wipe them down routinely with a cleaning agent or damp cloth works nicely. This goes for the rack, basket, base and casters. Be sure to wipe the carts down immediately with a dry cloth to remove the moisture and debris – keeping your carts bright and dry. Your customers will notice and appreciate this routine maintenance.

The trickiest part of this maintenance process is taking care of the casters – the only moving parts on a laundry cart. The raceway, which allows the caster to swivel, and the internal precision bearings, which allow the caster to roll, are the two “Achilles Heels” of a caster. This is due to the fact that these two components tend to attract hair, lint and other debris, causing the caster to make noise, not roll smoothly or even lock up. Think about the last time you were at the supermarket and the shopping cart you were pushing had a jammed wheel full of hair, lint and other debris – not a pleasant experience!

Here are two options you have to solve this caster maintenance problem, depending on the casters you have.

Non-R&B Casters

- If necessary you can open the raceway to clean the bearings and repack them with grease. Ultimately, an open raceway will yield the same problem again and again. Avoid using a degreaser lubricant (like WD-40) as this will be counter-productive.

- Next, remove the axle bolt and nut from the caster to remove the debris that has wound around the axle nut and bolt.

- Once you have removed the nut and bolt, clean the inside of the caster as much as possible. Clean the nut, bolt and center axle as much as possible with a clean rag. You will likely find that the bearings inside need to be removed and cleaned.

- Replace the nut and bolt until properly tightened. Your customers depend on your carts and expect them to function properly. Depending on how much traffic your laundromat gets, you may have to clean the casters every month. Poorly functioning carts can cost you customers!

R&B's Clean Wheel System™ Casters

R&B Wire’s proprietary Clean Wheel System™ casters come standard on all of our laundry carts. These 5" casters are equipped with our proprietary "Clean Wheel System", featuring our plastic raceway cover and Thread Guard, both designed to minimize any debris pick up. If they ever do pick up any debris, it should be easily removed. We are proud to say that these casters are designed to require far less ongoing maintenance than generic casters.